A Heartfelt Testimonial from Mina Product Development Co. Inc.

At CH America, we are deeply grateful for the kind words and support from Mina Product Development Co. Inc. Their longstanding expertise in plastic injection

First launched in 2008 The SM Dual Platen Servo Drive injection molding series has gone over relentless improvements of the past years and remains one of our flagship machine series.

They deliver high precision, high stability, high speed, and ultimate mold protection without any of the traditional compromises.

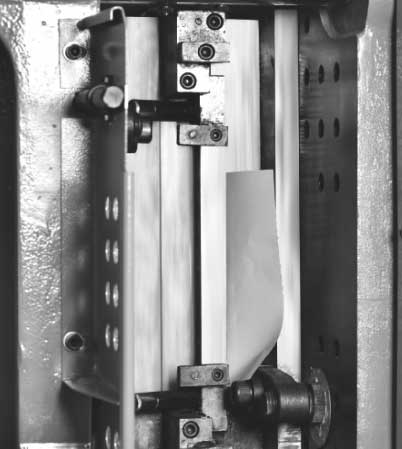

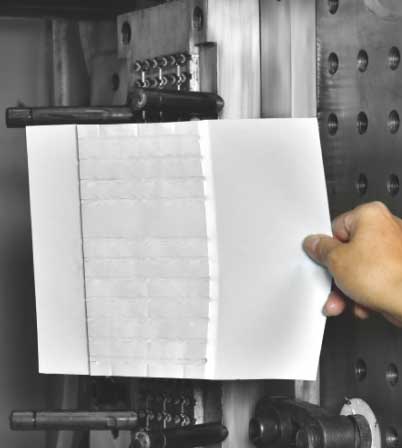

High precision linear potentiometers are used for the clamping, injection and ejector axes which, when combined with high-optimised algorithms, enables superior low-pressure mold protection-effective even with obstacles thinner than 0.1mm (or the thickness of a sheet of paper)

Low-pressure mold protection causes clamp to open

Stay in touch and get the latest from CH America. Stay informed with product updates, launches, news, trade shows and much more.

CH America has several warehousing locations nationwide in addition to our 40,000 square foot corporate office and warehouse in Torrington, CT, 110 miles northeast of New York City and 100 miles southwest of Boston.

At CH America, we are deeply grateful for the kind words and support from Mina Product Development Co. Inc. Their longstanding expertise in plastic injection

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

Choose Your Region

The Chen Hsong Group has offices and distributors all around the globe.

Select your region from below or search our global list of distributors.