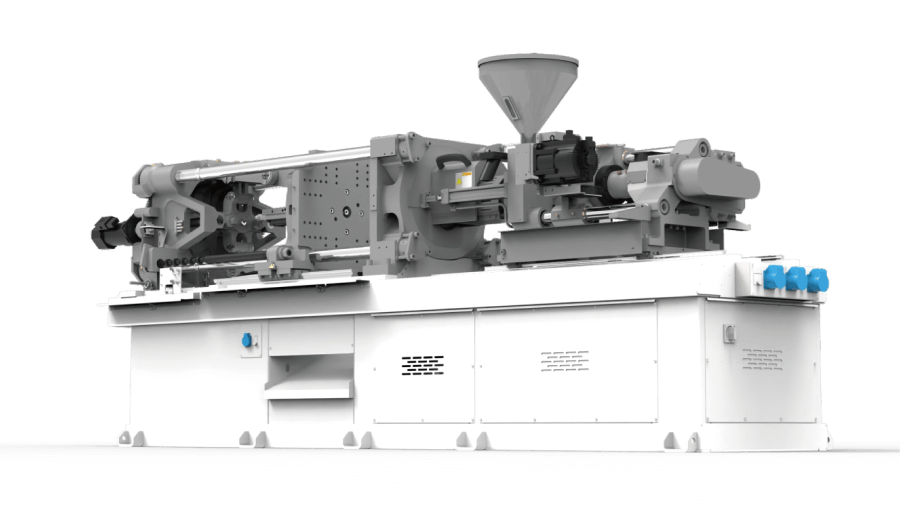

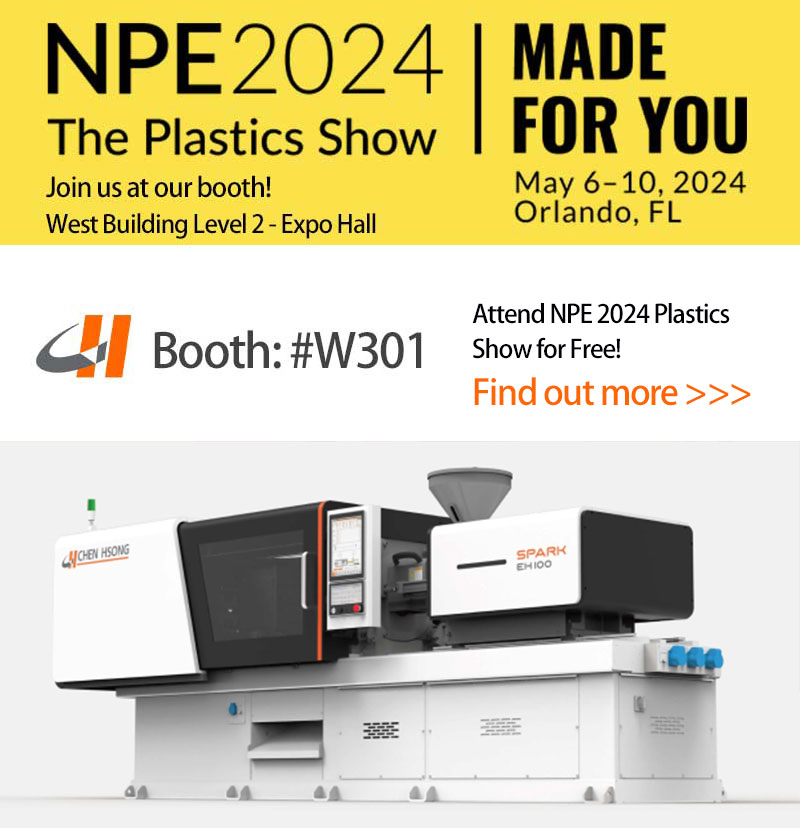

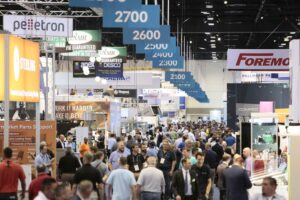

NPE 2024 Orlando Exhibition Explore the Latest Innovations & Technologies in the Plastics Industry.

CH America will be exhibiting at NPE 2024, Mark your calendars and make sure to join us for an opportunity to explore the latest innovations and technologies in the plastics industry.